The harvesting multitool

COMBI-1010

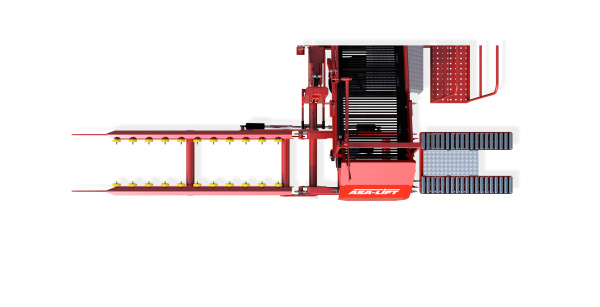

The Combi-1010 is the successor to the Combi-1000, the single row top-lifter known for its robust construction and excellent harvesting performance.

Overview

Click here to see a video of the Combi-1010C

Toplifting section

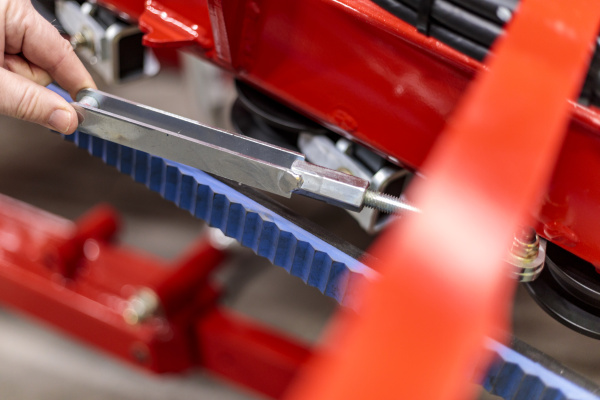

The Combi-1010 is the first mounted harvester to introduce the ASA-LIFT 374” Super Grip belt arm, which is used on our trailed and self-propelled series. This belt arm is designed with a new profile and a strong construction, and easily replaceable wear-parts. The belt arms pressure can manually be adjusted to perfectly suit your crop. Multiple root cleaners can be attached to further improve the effectiveness of cleaning in resilient soil and having. Easily adjust tension or change belts on belt arm with the straightforward quick-release system - a single tool releases belts and tension can then be adjusted by turning a spindle with fingers. To protect the belt arm in case of accidentally being run into the ground, the front now has break-away bolts that break off, instead of the belt arm bending. A spring system protects by temporarily relieving the entire belt arm.

Sharelifting

An alternative UT55 pickup makes the Combi-1010 capable of doing share-lifting instead of topllifting. Different web-types suit different crops, the hedgehog and hydraulic shakers below the web makes cleaning very efficient. Load crops into boxes or trailers with either the box loading or elevator.

Sorting table

The Combi-1010 C model comes with a 700mm wide sorting table, next to a large standing platform which facilitates the ideal work setting for crop-sorting. The platform is spacious enough for two persons to move around freely. The topped crop goes down onto a PVC covered web for manual sorting, and continues to the depositor.

Box platform

The machine has a great variation of box platforms with space from either 1 box, up to 5 boxes. When driving on roads, the platform can be folded to meet required rules. Alternatively an elevator solution can be used for loading directly into trailers.

Rollers ensure that boxes effortlessly depart the magazine, and are placed onto the ground Boxes are firmly placed onto a hydraulically controlled chain controlled by the operator. The front of the hydraulic box magazine, lowers to the ground, to pick up boxes. Can be fitted

with a chain drive that pulls boxes onto magazine. A hydraulic depositor is included, which lowers into the box to soften the drop and minimize damage.

Elevator

The Combi-1010E has a 63 cm wide, three-stage elevator build to ensure high capacity with minimum damage. 125 mm rubber flights which prevents the crop rolling back.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates