scroll and find out more...

Self-propelled harvester - 4-row | VARITRON 470

4-row, 7 t NonstopBunker, high separation performance, wheels

Self-propelled harvesters excel with the perfectly matched combination of performance, driving comfort and manoeuvrability. The resulting harvest reliability, even under the most difficult conditions, plays a decisive role in many cases. With the VARITRON 470, GRIMME offers a 4-row self-propelled harvester which can be equipped with an extensive range of separators. The VARITRON 470 achieves a high degree of manoeuvrability thanks to its wheeled chassis, which is fitted with large-volume tyres as standard and gives extreme soil protection in all conditions. The 7 ton bunker is used the whole time with effective capacity thanks to the rotating bunker web. A large number of automatic features for the harvesting process, which can all be conveniently controlled from the premium cabin, ensure a maximum working and driving comfort.The connection to myGRIMME facilitates the storage and retrieval of machine data and task data. And, thanks to the SmartView video system, you always have an overview of the most important machine functions.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

Good overview and low maintenance costs.

The intake web and first main web are designed as webs at full width over 4 rows. This prevents blockages and provides a good overview of the entire intake. In addition, this minimises the maintenance effort and increases the ease of servicing.

High ground compaction protection and manoeuvrability

The large dimensioned tyres ensure a high degree of ground protection and the steering angle of up to 63° enables high manoeuvrability on the headland. For the smallest possible turning circle, the wheels of the rear axle can be turned by +/- 20°.

Intuitive Operating Concept

The unique ErgoDrive operating concept provides the basis for a convenient workplace. For satisfied work: A multi-functional joystick and keypad which is located in the ergonomic armrest, both with the possibility of individual programming of all main functions are integrated to fulfil all the requirments of the driver.

For additional cleaning and sieving

OptiBag, is an elastic, high capacity elevator made of polyurethane. The volume of the deep pockets is about 20 % higher than the traditional systems, made of canvas. This ensures very high conveying capacities. The perforated deep pockets provide additional sieving of residual soil in sticky conditions. The special shape of the pockets promotes the gentle handling and transfer of the crop.

NonstopBunker

The unique and patented 7 t NonstopBunker allows a complete refilling of the bunker after unloading with maximum crop protection. The continuous, very rapid overloading enables an increase in harvest performance of up to 30% compared to harvesters with conventional standard bunkers.

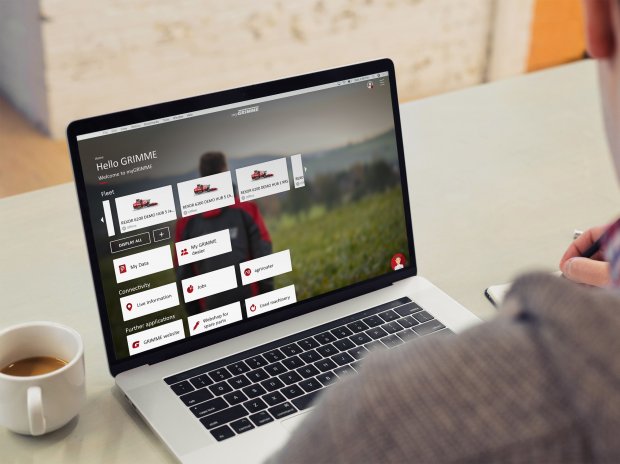

myGRIMME - Your digital gateway to GRIMME

With the virtual machine file, you have all your machines, services and documents available - anytime at a glance. The smart documentation records and analyses all machine jobs quickly and without manual data entry. Order the perfect spare parts for your machines easily and intuitively in the myGRIMME Shop.

Discover now!

Benefits

- Digging unit

- TerraControl: Digging depth adjustment, which ensures also in changing conditions an optimum sieving output and high gentle crop handling at the same time.

- TerraDisc: Digging with driven disc coulter and without diablo roller (therefore no additional soil compaction) and depth control via skids.

- High acreage performance and separating effect.

- Unique variety of various separators, such as MultiSep or Roller Separator, Vario-RS or fine haulm elevator for an optimum adaption to individual digging conditions and maximum performance of separation.

- main characteristic of the GentleFlow concept is, that the main web channel and the following separators are designed for the full width of the machine. At the point, where the rear axle is connected to chassis, the crop flow needs to be divided. This is done in a very gentle way.

- The full width main web channel reduces the risk of blockages, improves the distribution of the crop, enhances easy maintenance and gives a clear view to control the digging process (only one camera per main web section is necessary).

- To remove and to prevent any blockage, all main webs, the fine haulm elevator and the ring elevator can be individually and conveniently reversed from the operator cab.

- The MultiSep performs also on cloddy, sticky soils and soils containing small stones a low-loss and effective trash separation.

- Thanks to its patented design of bunker web, the NonstopBunker always offers a large effective capacity. Furthermore it is significantly more gentle than traditional systems.

- Chassis

- For fast turning manoeuvres at the headlands the steering angle at the front axle is up to 63°, at the rear axle up to 20°, resulting in an inner turning circle of only 6 m.

- Perfectly comfortable

- Relaxed working thanks to noise-insulated cab, premium driver's seat with extra-high backrest and headrest, maximum suspension comfort, seat heating and air-conditioning system and powerful LED lighting system

- Speedtronic-Web: Completely automatic speed control of the main webs depending on the driving speed and the load on the main webs.

- Speedtronic-Elevator: Automatic speed control of the elevator, based on the filling level with crop for maximum crop protection

- MemoryControl: For saving and "re-use" of specific harvest parameters

- ErgoDrive operating concept: Intuitive, clearly structured user interface with easy-to-understand symbols on the CCI 1200 operator terminal. In combination with a multi-functional lever and a keypad which are integrated into an ergonomic armrest, both with the possibility of individual programming of all main functions to the first operator level - for direct access to all important features of the machine.

- SmartView: The video system includes a 12 inch touch screen with the feature to zoom-in, live slow motion, live image transmission via WiFi, Visual Protect Pro and the possibility to record the displayed image.

- Visual Protect Pro: Automatically, simultaneous switch-on of several cameras, where a new adjustment was carried out or a critical situation has been noticed (risk of a separator blockage e.g.), so that the driver can react and prevent further blockages or damages of the machine.

- SideView: The video monitoring system, which provides a real display of the whole machine surrounding without any blind spots

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Pulled diablo roller intake unit with TerraControl

- Row width 75 cm

- main characteristic of the GentleFlow concept is, that the main web channel and the following separators are designed for the full width of the machine. At the point, where the rear axle is connected to chassis, the crop flow needs to be divided. This is done in a very gentle way.

- Intake web, 1st main web and 2nd main web hydraulically driven with independent speed adjustment

- Intake web, first and second main web, cone crop divider, fine haulm elevator and ring elevator are reversible

- Hydraulically driven and speed adjustable rocker agitator in 1st main web

- Extracting roller against 1st main web

- 1200 mm wide ring elevator with canvas

- Speedtronic-Elevator: Fully automatic speed control of the elevator, depending on its load

- NonstopBunker: 7.0 tons unloading bunker with reversing bunker floor

- Bunker web with canvas

- Bunker chain greasing system

- 2 steerable front wheels 270 / 95 R 54 with hydraulic side travel +/- 100 mm, steering angle +/- 63°

- 2 steerabel rear wheels 1 x 900/ 60 R 32 l/h-side, 1 x 1050/50 R32 r/h-side, steering angle +/- 20°

- Hydrostatic single wheel drive with on - demand traction control (ASR)

- Mercedes-Benz (MTU) engine OM 470 LA: 340 kW / 460 HP stage V, using SCR exhaust technology (AdBlue)

- Driver cab with 6 LED-working lights, heated and electrical adjustable mirrors and windshield wipers on all windows.

- Compressor

- Comfort cab: Air-suspended seat, Climatronic, pneumatic folding mirrors, audio system prepared for Bluetooth mobile telephone system, windshield wipers and sunshade

- ErgoDrive operating concept with multi-functional lever (= individual configuration of all main functions to the first operator level for direct access), keypad integrated into an ergonomic armrest and one touch-screen terminal type CCI 1200.

- MemoryControl: For saving and "re-use" of specific harvest parameters

- Camera package SmartView BASIC including 8 cameras, integrated zoom, live slow motion, live image transmission via WLAN, 12 inch touch screen monitor and Visual Protect Pro

- Telemetric-unit called "GRIMME SmartConnect", as standard, with free connectivity to myGRIMME

Technical data

VARITRON 470

| Dimensions | |

|---|---|

| Length | 12810 - 15600 mm |

| Width at row width 75 cm | 3490 mm |

| Width at row width 90 cm | 3870 mm |

| Height | 4000 mm |

| Weight | |

| Permitted total weight | 26000 kg |

| Front axle load | 7000 kg |

| Rear axle load | 19000 kg |

| Main webs | |

| Width of intake web, row width 75 cm | 2970 mm |

| Width of intake web, row width 90 cm | 3600 mm |

| Sieving area of intake web, row width 75 cm | 4,1 m² |

| Sieving area of intake web, row width 90 cm | 4,7 m² |

| Sieving area of 1st main web, row width 75 cm | 5,9 m² |

| Sieving area of 1st main web, row width 90 cm | 6,5 m² |

| 2nd main web sieving area | 6,9 m² |

| Intake web pitch (choice of) | 35 / 40 / 45 / 50 mm |

| 1st main web pitch (choice) | 28 / 32 / 35 / 40 / 45 / 50 mm |

| 2nd main web pitch (choice) | 28 / 32 / 35 / 40 / 45 mm |

| Elevator | |

| Ring elevator transport width | 1200 mm |

| Bunker | |

| Capacity | 7000 kg |

| Unloading height | 4350 mm |

| Wheels | |

| Front wheels at 75 cm row width | 2x 270/95 R54 |

| Front wheels at 90 cm row width | 2x 300/95 R52 |

| Rear right | 1050/50 R32 |

| rear left | 900/60 R32 |

| Steering angle | |

| Front | 63 ° |

| Rear | 20 ° |

| Chassis and engine | |

| Transport speed | 20 / 25 / 30 km/h |

| Engine output power with emission stage V | 340 / 460 kW/HP |

| Engine output power with emission stage IIIA | 320 / 435 kW/HP |

| Fuel tank capacity | 600 l |

| AdBlue tank capacity | 40 l |

| Hydrostatic drive | x |

| Levelling at slopes | 4,2 ° |