scroll and find out more...

Planting technology - Belt planter | GB 430

4-row, 3 t hopper, for high output

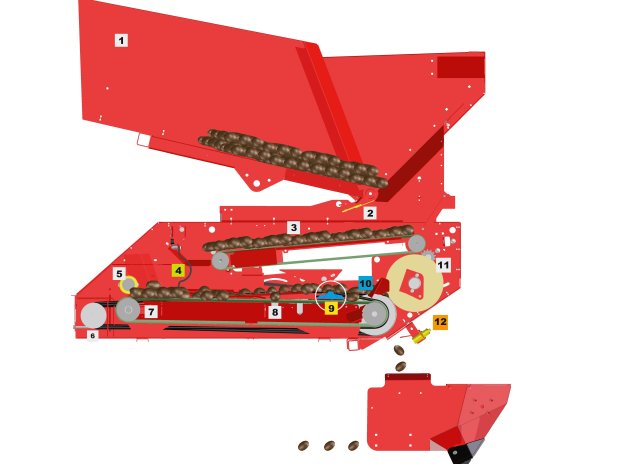

The GB 430 belt planter, is the perfect four-row choice for fast, efficient and gentle planting of potatoes. The design of the belt planting element makes it possible to plant non-calibrated tubers or oblong shaped varieties. With suitable, calibrated tuber sizes, higher working speeds of up to 10 km/h can be achieved, which can lead to a significant increase in output. The GB 430 belt planter is designed both for conventional planting in ridges and for planting in separated beds. Thanks to two different versions of the chassis, the machines can be perfectly adapted to different applications in terms of ridge construction. The efficiency and performance of the machine can be increased by the integration of under-root fertilization, ridge shaping, erosion control and the application of granules as well as the application of liquid seed dressing or furrow treatment agents. The ISOBUS operator terminal CCI 800 or CCI 1200 with intuitive user interface GDI and various diagnostic options offer a high level of operating comfort and provides relief for the driver. The machine can be equipped with Clever Planting and Section Control as an option.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

- Downloads

High capacity

Driving speed of up to 10 kmph realize a high output, depending on the crop size and variety, planting distance, machine equipment and soil conditions.

Highest manoeuvrability

Chassis with gantry pivot axle, high agility due to a steering angle of 35°.

Planting in separated beds

In combination with the integrated furrow openers, the Flow-Board XL ensures that the seed potatoes are always covered with a constant layer of soil.

Combined plant protection

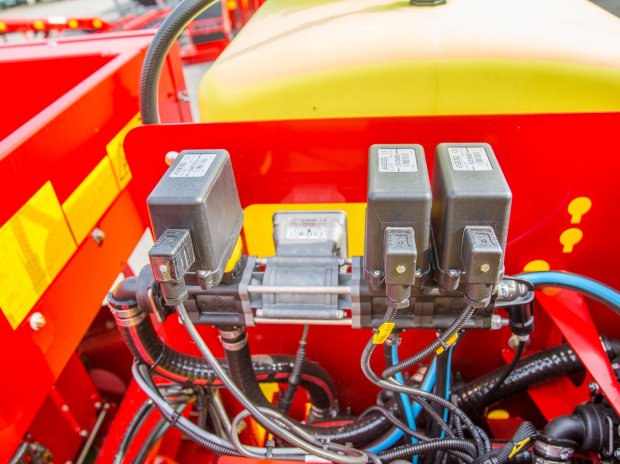

GRIMME tank system TS 820, authorized for liquid chemicals to be applied onto the seed potatoes and/or into the furrow.

Clever Planting

Increased share of marketable crop due to a improved, homogeneous growth and tuber size in the rows next to the spraying tracks. This is achieved by an infinitely adjustable, reduced tuber spacing and the resulting change in competition for light and nutrients along the spraying tracks.

Large-volume ridges

The shaping board XL creates ridges with a large volume, so that there is enough space for a large tuber-nest.

Ridge shaping on light soils

For an improved water absorption on light soils, cage rollers can be used in combination with spring-loaded ridging bodies.

Gentle treatment

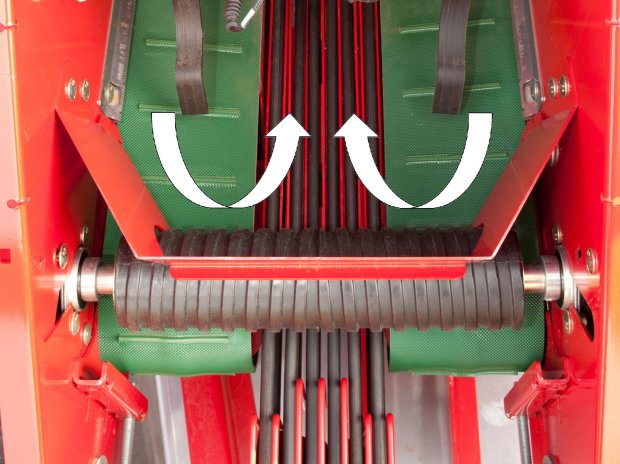

Box turn unit for a gentle treatment of the seed tubers by minimal handling and movement.

Video: TerraProtect PRO

Video: The belt planter GB 430 at work

Benefits

Configuration

Drive

Assistance systems

Furrow openers / depth control

Tipping hopper

Box turning unit

Traditional planting

Bed planting

Liquid chemicals to be applied onto the seed potatoes / into the furrow

Fertiliser spreading

Granulate spraying

Drawbar

Chassis

Control Systems

Assistance systems

myGRIMME

- Working speeds of up to 10 kmph means high outputs are achieved, depending on the tuber size and variety, planting distance and soil conditions.

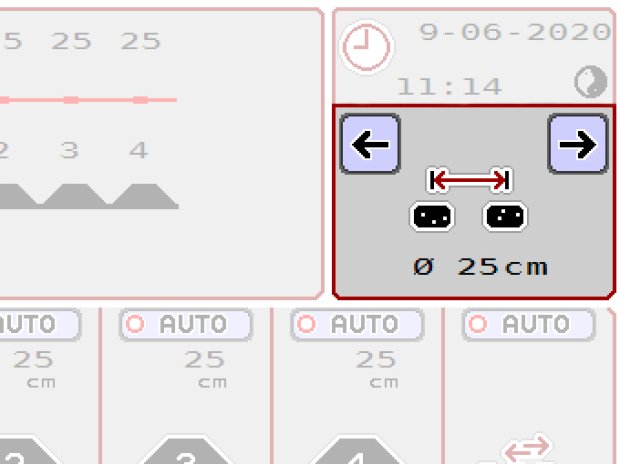

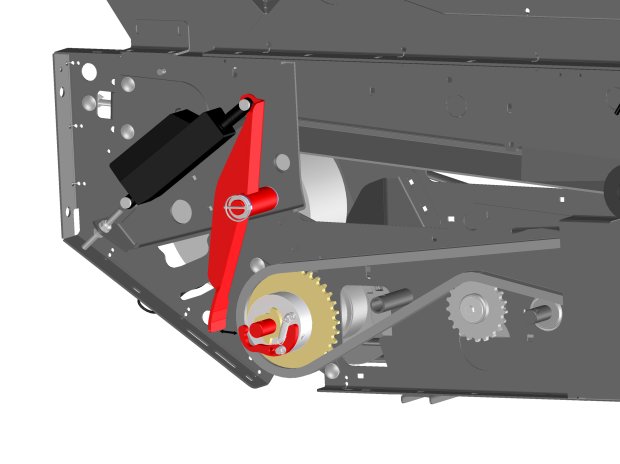

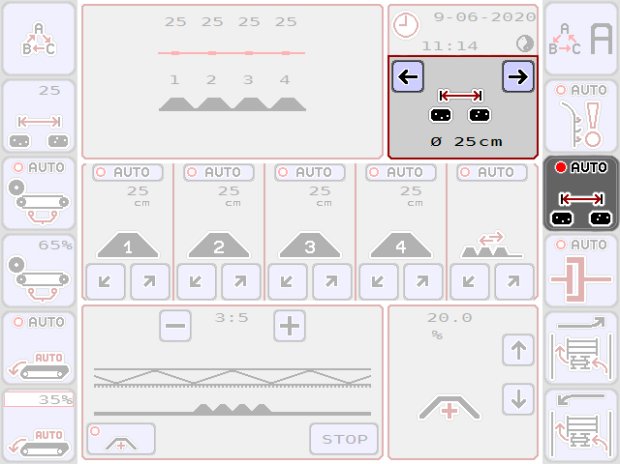

- The tuber spacing or the number of tubers per hectare can be adjusted from the operator terminal.

- Less seed potatoes are required with the automatic single row deactivation of the planting elements with Section Control.

- Clever Planting: Increased share of marketable crop due to an improved, even growth and tuber size in the rows next to the spray tracks. This is achieved by an infinitely adjustable, reduced tuber spacing and reduces the competition for light and nutrients along the spray tracks.

- The automatic, row dependent steering system via the hydraulic steering drawbar ensures a perfect centre tuber position in case of cultivation with pre-shaped ridges.

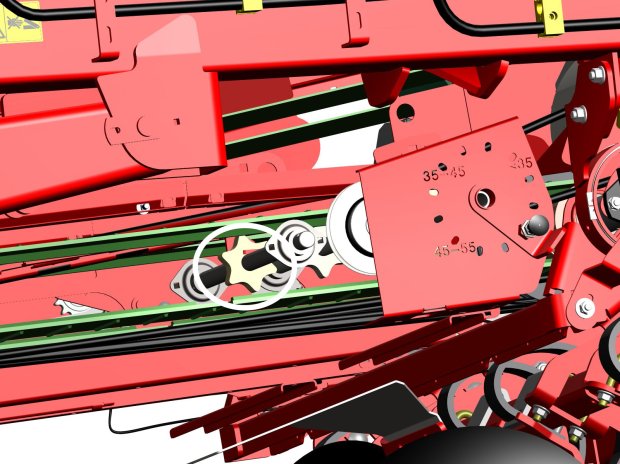

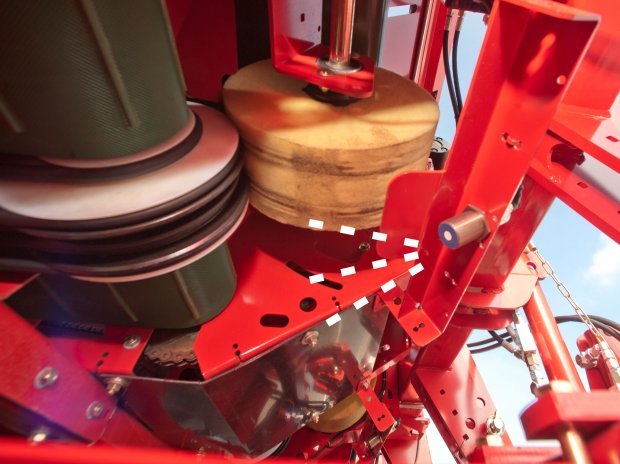

- For a precise singling of seed potatoes on slopes, the planting element can be levelled +/- 7° in relation to driving direction.

- Uniform growing through constant soil covering of the tubers via hydraulic depth control of the furrow opener and automatic shaping board steering. The planting depth can easily be controlled and adjusted from the cab.

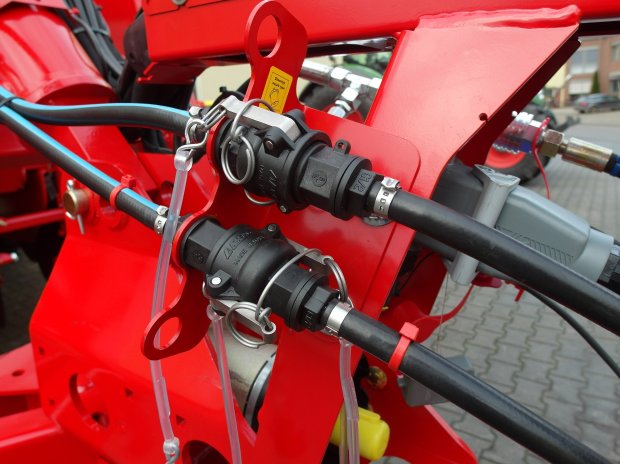

- The approved GRIMME barrel system ensures even application of the tuber with liquid chemicals and offers the driver many comfort functions.

- Simultaneous application of liquid chemicals and granulates for an optimal start of the vegetation. This is made possible by means of two physically separated chambers in the furrow openers, so that possible sticking and thus uncontrolled spreading is avoided.

- There are several versions for ridge shaping available for a perfect adaptation to different soil conditions.

- The optional four-wheel chassis ensures even weight distribution and can be combined with a variety of different ridge shaping options.

- The standard chassis with two wheels on the outside and a ridge shaping in front of the wheels is perfect for potato cultivation in beds and for a precise, central placement of the tubers on slopes.

- A Hydraulic steering axle and a large steering angle of up to 42° (chassis with two wheels) or 35° (chassis with four wheels) enable a high agility.

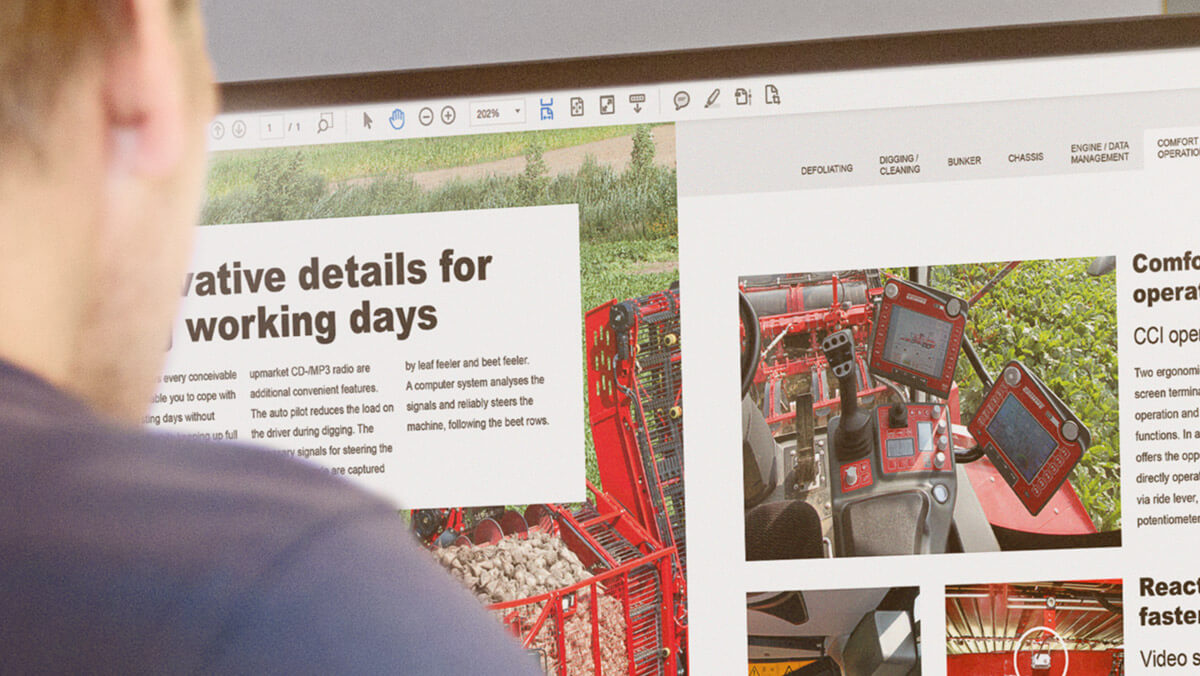

- The ISOBUS operator terminal CCI 800 or CCI 1200 with intuitive user interface GDI and various diagnostic options offer a high level of operating comfort and provides relief for the driver.

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

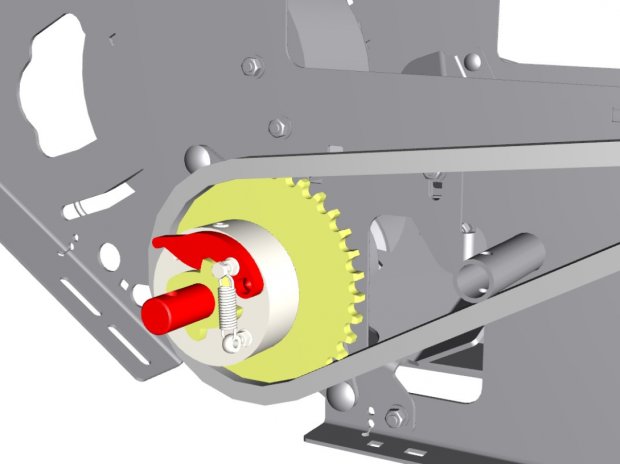

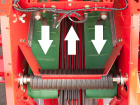

- 4 planting elements, hydraulically driven

- Hydraulically driven oscillator in the planting element

- 4 separate operated, hydraulically driven feeding belts

- Infinitely planting distance adjustment

- Pulled furrow openers in parallelogram with feeler wheel 16.5 x 6.50 - 8 AS

- Covering unit

- Row width 75 cm

- Tipping hopper capacity 3000 kg

- Mechanical telescope drawbar incl. hydraulic jack stand

- Tractor attachment with drawbar eye or hitch

- Chassis with 2 running wheels

- Wheels 270/95 R44

- Lighting system

- Hydraulic block

- Main electronic MDA

- ISOBUS operator terminal CCI 800

Technical data

GB 430

| Dimensions | |

|---|---|

| Length with axle incl. 2 outer running wheels without / with front frame | 6560 / 7300 mm |

| Length with gantry pivot axle incl. 4 running wheels without / with front frame | 5640 / 6380 mm |

| Length with spraying track lever and axle incl. 2 outer running wheels without / with front frame | 6560 / 7300 mm |

| Length with spraying track lever and gantry pivot axle incl. 4 running wheels without / with front frame | 7030 / 7770 mm |

| Width at row width 75 cm | 3300 mm |

| Height | 2800 mm |

| Height in transport position | 3200 mm |

| Filling height tipping hopper flat | 2230 mm |

| Support length with axle incl. 2 outer running wheels without / with front frame | 6560 / 7300 mm |

| Support length with gantry pivot axle incl. 4 running wheels without / with front frame | 5030 / 5770 mm |

| Overlapping length at the rear side | 1300 mm |

| Weight | |

| Empty weight with basic configuration | 4000 kg |

| Working width | |

| Row width | 75 - 90 cm |

| Number of rows | 4 |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Low hitch | x |

| Low hitch ball bearing (K 80) | x |

| Bunker | |

| Tipping hopper capacity | 3000 kg |

| Capacity at row width 90 cm | 3500 kg |

| Wheels | |

| Wheels (option 1) | 2x 270/95 R44 |

| Wheels (option 2) | 4x 280/85 R28 |

| Track width | 3000 mm |

| Track width adjustable up to | 3660 mm |

| Chassis and engine | |

| Transport speed (option) | 25 km/h |

| Tractor requirements | |

| Without shaping board (min.) | 60 kW |

| With shaping board (min.) | 90 kW |

| Oil flow | 50 l/min |

| Required control valves (single acting) | 2 |

| Required control valves (double acting) | 1 |