scroll and find out more...

Harvesting Technology - Windrower | WR 200

2-row, trailed, adaptable to various conditions, from 47 HP on

Potatoes and other root crops are harvested worldwide using various methods and degrees of mechanisation. With the windrower type WR 200, GRIMME offers a trailed harvester, which has been designed for various applications, using the well proven digging units from the 2-row harvesting technology of the SE series. Thanks to its easy handling and the minimum required tractor power of 47 hp, the modular designed harvester is the perfect machine to start mechanised harvest of potatoes and other root crops. Depending on the machine-model, the crop is deposited centrally or laterally behind the machine. Configured as a machine with centre deposit, the potatoes can either be collected by hand or picked up in a two-phase harvesting process after drying with a windrow intake. The reduced amount of adherent soil improves the suitability for long-term storage of the potatoes and results in a significant increase in performance of the following harvester. Equipped with a crop cross conveyor the harvester WR 200 can also be used in enhanced harvesting processes. In this case, the crop from two rows is deposited laterally between the next two neighbouring rows and then harvested together. In addition to protecting the crop and improving sieving performance, the "enhanced harvesting process" also significantly increases the output of the following potato harvester.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

Gentle crop intake

The mechanical ridge relief minimises clodding in heavy soils and thus ensures improved crop protection. In sandy soils the crop flow is also improved because the ridges will not fall apart.

High degree of agility and manoeuvrability

The axle steering improves agility and correction at slopes. In addition, the wheels can be moved to the centre position at the push of a button using the axle self-centre steering, further enhancing the driver's operating comfort.

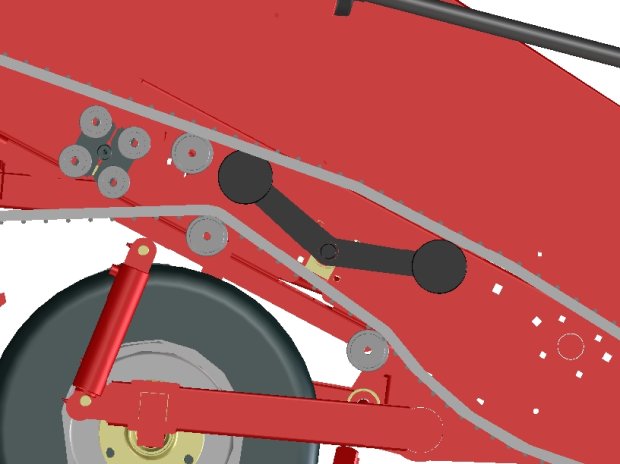

Stepless adjustment of the ascent-angle of the main web

The main web angle can be adjusted via hydraulic cylinders to adapt to a wide range of harvesting conditions. This not only increases ground clearance but also achieves an optimum compromise between sieving performance and crop protection.

For heavy digging conditions

The combination of a rocker agitator (option) with a rotary agitator ensure additional, gentle sieving on the first main web.

Benefits

- General information about WR

- Easy to pull but strong machine starting at 47 HP tractor power

- For row widths of 75 and 90 cm

- As standard with four spring loaded disc coulters and two diablo rollers for accurate depth control of the ridge intake.

- The drive and the digging units are taken from proven 2-row harvester technology

- Reliability and low maintenance also with high output

- A load-sensing kit to reduce oil heating and energy input is available

- WR 200 CE

- A bed level adjuster and a following bed roller ensure an even and slightly compacted surface, the harvested crop stays on the surface for better drying.

- With its long, continuously from the front to the back running main web, and a central, superficial deposit of the harvested tubers and no specific haulm separation, the machine is perfectly suitable for the entry into mechanised potato harvesting.

- WR 200 CHE

- Suitable for two-phase (delayed, discontinous) harvest process

- A bed level adjuster and a following bed roller ensure an even and slightly compacted surface, the harvested crop stays on the surface for better drying.

- Behind the long main web the machine is equipped with an extracting roller in order to remove haulm from the crop flow.

- Extracted haulm is deposited next to the potatoes, by use of a traverse haulm discharge conveyor.

- The windrowing machine with its counter-rotating hedgehog belt and a central, superficial deposit of the potatoes is ideally suited for the two-phase harvesting process. In this case the machine is followed by a single-row potato harvester.

- WR 200 CDW

- Suitable for two-phase (delayed, discontinous) harvest process

- A bed level adjuster and a following bed roller ensure an even and slightly compacted surface, the harvested crop stays on the surface for better drying.

- A long first main web, followed by a drop step onto the second main web ensure an improved sieving performance of impurities.

- Due to the central superficial depositing of the potatoes, gently guided by double scraper roller on both sides, the machine is ideally suited for the two-phase harvesting process in combination with a single or double row potato harvester.

- WR 200 S

- Suitable for two-phase fortified harvest process

- A long first main web, followed by a drop step onto a short second main web ensure a good sieving performance of impurities.

- Behind the first main web, an extracting roller separates the haulm and weed from the crop flow.

- The crop cross conveyor, which is mounted on the rear side of the main web, enables this machine to be used in an enriched harvesting process - in combination with a two-row potato harvester (2 + 2 = 4 rows).

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Intake width 580, 600 or 620 mm

- First main web with lock connection facilitates a quick change of the webs in changing harvesting conditions

- Centre retaining flap

- 2- or 3-piece share blade for optimum intake with different soil conditions

- 4 spring loaded disc coulters grant a blockage free potato intake

- 2 large haulm feed-in rollers minimize haulm blockages

- Wheels 10.0/75-15 AW for WR 200 CE and for WR 200 CHE

- Wheels 11.5/80-15.3 AS for WR 200 CDW and for WR 200 S

- Drive shaft with overload clutch to protect the machine

- Connection to tractor hydraulics

- Rotary agitator with manual adjustment of intensity

Technical data

5180-010 WR 200 CE

| Dimensions | |

|---|---|

| Length | 5700 mm |

| Width | 2280 mm |

| Height | 1890 mm |

| Weight | |

| Empty weight with basic configuration | 2800 kg |

| Tractor attachment | |

| Lower linkage category | 2 Cat. |

| Drive | |

| Input speed p.t.o.-shaft | 540 rpm |

| Main webs | |

| 1st main web width | 1700 mm |

| 2nd main web width | mm |

| 1st main web sieving area | 6 m² |

| 2nd main web sieving area | m² |

| Wheels | |

| Wheels | 10/75-15 AW |

| Chassis and engine | |

| Transport speed | 25 km/h |

| Tractor requirements | |

| Engine power (min.) | 35 kW |

| Required control valves (single acting) | 11 |

| Non-pressurized return flow | 1 |

| Required control valves (double acting) |

5180-020 WR 200 CHE

| Dimensions | |

|---|---|

| Length | 6660 mm |

| Width | 2280 mm |

| Height | 1890 mm |

| Weight | |

| Empty weight with basic configuration | 2800 kg |

| Tractor attachment | |

| Lower linkage category | 2 Cat. |

| Drive | |

| Input speed p.t.o.-shaft | 540 rpm |

| Main webs | |

| 1st main web width | 1700 mm |

| 2nd main web width | mm |

| 1st main web sieving area | 4,6 m² |

| 2nd main web sieving area | m² |

| Wheels | |

| Wheels | 10/75-15 AW |

| Chassis and engine | |

| Transport speed | 25 km/h |

| Tractor requirements | |

| Engine power (min.) | 35 kW |

| Required control valves (single acting) | 11 |

| Non-pressurized return flow | 1 |

| Required control valves (double acting) |

5180-030 WR 200 CDW

| Dimensions | |

|---|---|

| Length | 8500 mm |

| Width | 2340 mm |

| Height | 2360 mm |

| Weight | |

| Empty weight with basic configuration | 3230 kg |

| Tractor attachment | |

| Lower linkage category | 2 Cat. |

| Drive | |

| Input speed p.t.o.-shaft | 540 rpm |

| Main webs | |

| 1st main web width | 1700 mm |

| 2nd main web width | 1700 mm |

| 1st main web sieving area | 4,6 m² |

| 2nd main web sieving area | 3,5 m² |

| Wheels | |

| Wheels | 11.5/80-15.3 AS |

| Chassis and engine | |

| Transport speed | 25 km/h |

| Tractor requirements | |

| Engine power (min.) | 55 kW |

| Required control valves (single acting) | 12 |

| Non-pressurized return flow | 11 |

| Required control valves (double acting) | 1 |

5180-040 WR 200 S

| Dimensions | |

|---|---|

| Length | 6780 mm |

| Width | 2410 mm |

| Height | 1925 mm |

| Weight | |

| Empty weight with basic configuration | 2800 kg |

| Tractor attachment | |

| Lower linkage category | 2 Cat. |

| Drive | |

| Input speed p.t.o.-shaft | 540 rpm |

| Main webs | |

| 1st main web width | 1700 mm |

| 2nd main web width | 1700 mm |

| 1st main web sieving area | 4,6 m² |

| 2nd main web sieving area | 1,5 m² |

| Wheels | |

| Wheels | 11.5/80-15.3 AS |

| Chassis and engine | |

| Transport speed | 25 km/h |

| Tractor requirements | |

| Engine power (min.) | 55 kW |

| Required control valves (single acting) | 11 |

| Non-pressurized return flow | 11 |

| Required control valves (double acting) | 1 |