scroll and find out more...

Harvesting Technology - 2-row | SE 150-60

offset trailed machine, 2-row, up to 7.5 t bunker, for high output

The SE 150-60 bunker harvester was developed for high output but ensures gentle crop handling at the same time. The harvesters are available in four variants, which differ in the type of separator. This is suitable to customize the machine to the varying harvest conditions. Further more three bunker versions are available to choose from: 6 tonne standard bunker, 7.5 tonne large bunker as well as a 5.8 tonne unloading bunker. The machine is easy to handle, allows excellent view onto the digging unit and allows an easy maintenance. Additional options such as a video system relieving the driver are available.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

- Downloads

Universal separator

The separator type "UB" is a four-row finger scraper web and offers best separation properties on clod-rich soils with low stone content.

For stony conditions

The separator type "SB" is a six-row brush web which provides best separating properties on stony soils.

Two-phased harvest process

The machine can be equipped with a windrow intake for the delayed, discontinuous ("two-phases") harvesting process. The hydraulic depth adjustment and an infinitely variable speed of the brushes of the windrow-intake ensure a minimum of soil intake.

Direct transfer loading

The 5.8 t overloading bunker with overloading conveyor enables direct filling of a trailer during harvesting.

Variable use

Depending on the cultivation method (rows, beds, flat beds etc.), a wide range of different vegetables such as carrots, celery or red beet can also be harvested besides to potatoes.

Benefits

- Crop protection

- Main webs with high-cam belt for optimum gentle crop handling

- Reduced drop heights throughout the machine for a gentle crop transfer

- Active running side bars at the second main web for crop transfer without friction at the side walls

- Gentle handling into the bunker, resulting from low drop height

- Soft bunker floor, the bunker canvas is formed into pockets, which thus lead to a very good conveying effect.

- Gentle handling of the crop at bunker emptying, crop chute available as an option for direct box filling and addtional gentle crop handling

- High acreage performance and separating effect.

- Long first main web for effective sieving

- Haulm separation with wide deviner web, separation from the tubers over the whole length of the deviner web, minimum drop height

- 1st separator: Hedgehog web with double roller scraper to separate soil and fine haulm

- 2nd separator: The separator consists of a circulating hedgehog web with double scraper roller for separating soil, fine herbs and fine haulm. Alternatively, a combination of the hedgehog web with one smooth and one spiral roller can be selected for an increased conveying capacity and reduced risk of clogging.

- The machine can be equipped with an XXL separator for an enormous increase in performance and a throughput increased by up to 40%.

- Infinitely adjustable finger web, for an optimum setting of the trash separation.

- Bunker filling optimization to increase the bunker capacity.

- With an enlarged axle, the 7.5 t version can be selected instead of the 6 t bunker.

- Overloading bunker: Increased performance via gentle unloading during digging

- Chassis

- Offset trailed machine: Tractors with wide wheels ensure an increased traction

- The hydrostatic wheel drive with wide-angle drive shaft provides additional tractive force.

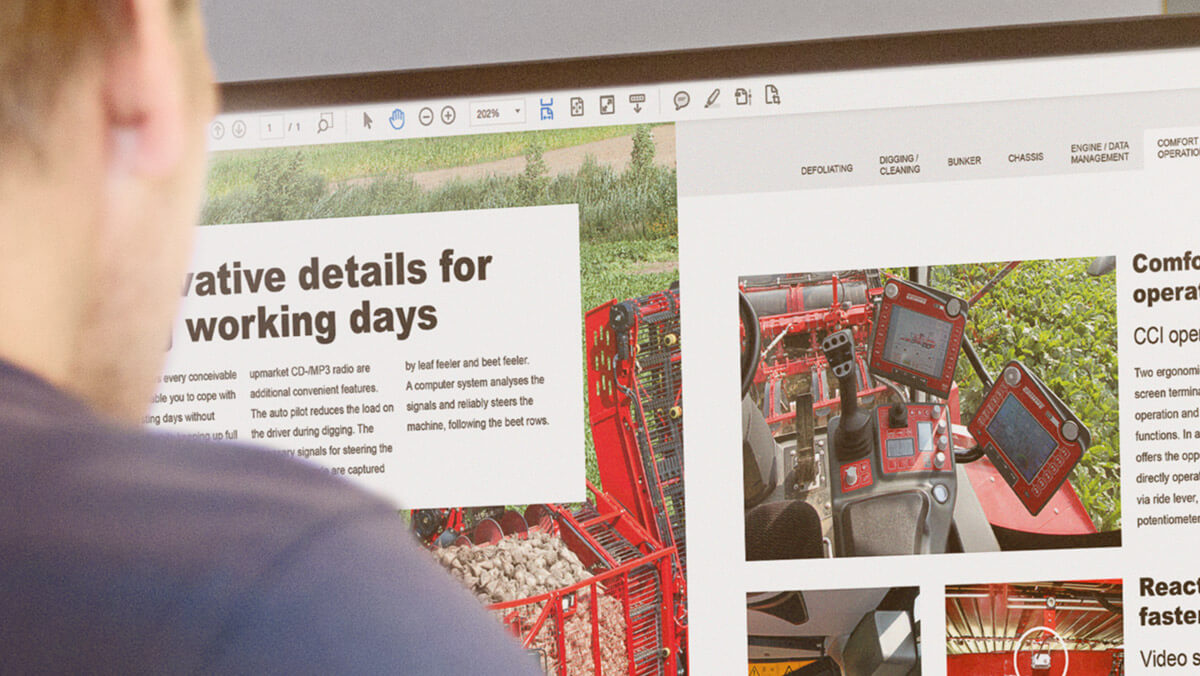

- Perfectly comfortable

- Digital operator terminal incl. colour display, touch-screen function and digital machine diagnostics realize a high operator comfort

- Video system for improved monitoring of the main webs and separators, to enable an optimum machine operation

- Due to the maintenance-free drive for the second main web and the deviner web, wear is minimized.

- Speedtronic-Sep: The load dependant and fully automatic speed control system for the separators and picking web relieves the driver from manual tasks and increases output.

- Clean Control: For saving and "re-use" of specific harvest parameters

- Visual Protect: Automatically switch-on of cameras, where a critical situation has been noticed (risk of a separator blockage e.g.), so the driver can react faster and prevent the blockage

- Versatility

- The machine can be equipped with a windrow intake for the delayed, discontinuous ("two-phases") harvesting process.

- Depending on the cultivation method (rows, beds, flat beds etc.), a wide range of different vegetables can also be harvested besides potatoes.

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Offset pulled intake section with pulled, spring loaded disc coulters

- Drawbar hitch under the PTO shaft

- Hydraulic drawbar steering

- Hydraulic jack stand

- Hydraulic axle steering

- Wheels 600/55-26.5

- Automatic axle self-centre steering and automatic levelling

- Automatic ridge self-centre steering

- Automatic ridge relief resp. ridge pressure regulation

- Stainless steel in swing frame

- Rocker agitator in the first main web

- Slip control for the first separator and the second main web

- First main web 28, 32, 35, 40, 45 or 50 mm pitch between rods (as standard with lock connection)

- Second main web 28, 32, 35, 40 or 45 mm pitch between rods (as standard with overlapping connection)

- Manual adjustable triangular rollers (6 pieces) below the first main web.

- Deviner web with scraper, (200 or 280 mm pitch)

- Self-hydraulic system to drive the separators

- First separator - hedgehog web with triple scraper roller

- Second separator - hedgehog web with double scraper roller

- The Third separator can optionally be configured as separator type "UB" (with finger web), as separator type "NB" (with double scraper roller) or as separator type "SB" (with brush web).

- Picking table platform on both sides of the picking table (not on NB)

- Lowering of the final conveyor

- Bunker unloading height 4200 mm

- Hopper capacity 6000 kg

- 2-step motor for bunker emptying

- Warning system for tractor driver

- Brake system and lighting system

Technical data

4160-010 SE 150-60 UB

| Dimensions | |

|---|---|

| Length | 11650 mm |

| Width | 3000 / 3300 mm |

| Height | 4000 mm |

| Weight | |

| Empty weight with basic configuration | 9500 kg |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Drive | |

| Input speed p.t.o.-shaft | 540 / 1000 rpm |

| Main webs | |

| 1st main web width | 1500 mm |

| 2nd main web width | 1700 mm |

| 1st main web sieving area | 4,13 m² |

| 2nd main web sieving area | 6,63 m² |

| Separators | |

| Deviner web width | 1700 mm |

| 1st separator width | 1300 mm |

| 2nd separator width | 730 mm |

| 3st separator width | 1300 mm |

| Picking table | |

| Width | 1100 mm |

| Trash web width | 340 mm |

| Picking personal | 2 + 2 |

| Bunker | |

| Capacity | 6000 kg |

| Unloading height | 4200 mm |

| Wheels | |

| Wheels | 600/55-26.5 |

| Chassis and engine | |

| Air brake | x |

| Hydraulic brake | x |

| Transport speed (option) | 25 - 40 km/h |

| Tractor requirements | |

| Engine power (min.) | 95 kW |

| Oil flow | 34 l/min |

| Required control valves (single acting) | 1 |

| Required control valves (double acting) | 1 |

| Permitted bearing load drawbar | 2500 kg |

4160-015 SE 150-60 UB NEW

| Dimensions | |

|---|---|

| Length | 11650 mm |

| Width | 3000 / 3300 mm |

| Height | 4000 mm |

| Weight | |

| Empty weight with basic configuration | 9500 kg |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Drive | |

| Input speed p.t.o.-shaft | 540 / 1000 rpm |

| Main webs | |

| 1st main web width | 1500 mm |

| 2nd main web width | 1700 mm |

| 1st main web sieving area | 4,13 m² |

| 2nd main web sieving area | 6,63 m² |

| Separators | |

| Deviner web width | 1700 mm |

| 1st separator width | 1300 mm |

| 2nd separator width | 730 mm |

| 3st separator width | 1300 mm |

| Picking table | |

| Width | 1100 mm |

| Trash web width | 340 mm |

| Picking personal | 2 + 2 |

| Bunker | |

| Capacity | 6000 kg |

| Unloading height | 4200 mm |

| Wheels | |

| Wheels | 600/55-26.5 |

| Chassis and engine | |

| Air brake | x |

| Hydraulic brake | x |

| Transport speed (option) | 25 - 40 km/h |

| Tractor requirements | |

| Engine power (min.) | 95 kW |

| Oil flow | 34 l/min |

| Required control valves (single acting) | 1 |

| Required control valves (double acting) | 1 |

| Permitted bearing load drawbar | 2500 kg |

4160-020 SE 150-60 SB

| Dimensions | |

|---|---|

| Length | 11650 mm |

| Width | 3000 / 3300 mm |

| Height | 4000 mm |

| Weight | |

| Empty weight with basic configuration | 9500 kg |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Drive | |

| Input speed p.t.o.-shaft | 540 / 1000 rpm |

| Main webs | |

| 1st main web width | 1500 mm |

| 2nd main web width | 1700 mm |

| 1st main web sieving area | 4,13 m² |

| 2nd main web sieving area | 6,63 m² |

| Separators | |

| Deviner web width | 1700 mm |

| 1st separator width | 1300 mm |

| 2nd separator width | 730 mm |

| 3st separator width | 1300 mm |

| Picking table | |

| Width | 1100 mm |

| Trash web width | 340 mm |

| Picking personal | 2 + 2 |

| Bunker | |

| Capacity | 6000 kg |

| Unloading height | 4200 mm |

| Wheels | |

| Wheels | 600/55-26.5 |

| Chassis and engine | |

| Air brake | x |

| Hydraulic brake | x |

| Transport speed (option) | 25 - 40 km/h |

| Tractor requirements | |

| Engine power (min.) | 95 kW |

| Oil flow | 34 l/min |

| Required control valves (single acting) | 1 |

| Required control valves (double acting) | 1 |

| Permitted bearing load drawbar | 2500 kg |

4160-030 SE 150-60 NB

| Dimensions | |

|---|---|

| Length | 11650 mm |

| Width | 3000 / 3300 mm |

| Height | 4000 mm |

| Weight | |

| Empty weight with basic configuration | 9500 kg |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Drive | |

| Input speed p.t.o.-shaft | 540 / 1000 rpm |

| Main webs | |

| 1st main web width | 1500 mm |

| 2nd main web width | 1700 mm |

| 1st main web sieving area | 4,13 m² |

| 2nd main web sieving area | 6,63 m² |

| Separators | |

| Deviner web width | 1700 mm |

| 1st separator width | 1300 mm |

| 2nd separator width | 730 mm |

| 3st separator width | mm |

| Picking table | |

| Width | 900 mm |

| Trash web width | mm |

| Picking personal | 2 |

| Bunker | |

| Capacity | 6000 kg |

| Unloading height | 4200 mm |

| Wheels | |

| Wheels | 600/55-26.5 |

| Chassis and engine | |

| Air brake | x |

| Hydraulic brake | x |

| Transport speed (option) | 25 - 40 km/h |

| Tractor requirements | |

| Engine power (min.) | 95 kW |

| Oil flow | 34 l/min |

| Required control valves (single acting) | 1 |

| Required control valves (double acting) | 1 |

| Permitted bearing load drawbar | 2500 kg |