scroll and find out more...

Harvesting Technology - 1-row | SE 140

Off-set trailed, 1-row, 4 t bunker, for medium sized fields

The SE 140 is an agile and at the same time powerful bunker harvester. With its 4-tonne bunker, it is specially designed for medium-sized farms and cultivation areas. The intake of the machine is perfectly visible from the driver's seat. The crop is then transported by first and second main web. The "SE- principle" excelled due to a combination of soil-sieving, an inclined conveyor and crop separation. Optionally, two different types of separators are available for the separation of stones and clods. Thanks to the large picking table, potential trash can be removed by hand. Thanks to its compact and sophisticated machine concept, the SE 140 is a very easy to operate, adjust and maintain.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

- Downloads

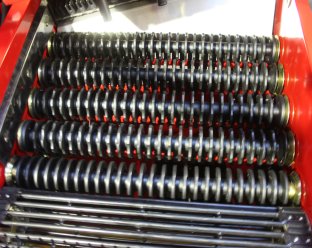

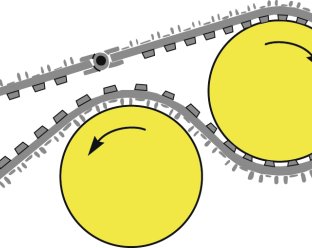

Universal separator

The separator type "UB" is a triple-row finger scraper web and offers best separation properties on clod-rich soils with low stone content.

Soils with high content of stones

The separator type "SB" is a five-row brush web which provides best separating properties on stony soils.

Wide intake

An intake channel width of 850 mm can be selected for sandy soils to increase the amount of soil on the first main web.

Gentle filling

The bunker outlet with integrated drop brake on the rolling floor bunker is used for the gentle filling of crates and transport vehicles. A hydraulic folding mechanism lifts the bunker outlet out of the crop flow and thus enables the filling of high transport vehicles at full width of the bunker.

Benefits

- Crop protection

- Main webs with high-cam belt for optimum gentle crop handling

- Reduced drop heights throughout the machine for a gentle crop transfer

- Active running side bars at the second main web for crop transfer without friction at the side walls

- Gentle handling into the bunker, resulting from low drop height

- Soft bunker floor, pockets in the bunker cloth ensure a very good dragging effect

- Gentle handling of the crop at bunker emptying, crop chute available as an option for direct box filling and addtional gentle crop handling

- High acreage performance and separating effect

- Short first main web for an effective sieving, simple to be changed

- Haulm separation with wide deviner web, separation from the tubers over the whole length of the deviner web, minimum drop height

- 1st separator: Hedgehog web with double roller scraper to separate soil and fine haulm

- Infinitely adjustable finger web, for an optimum setting of the trash separation.

- Bunker filling optimization to increase the bunker capacity.

- Small potatoes (triples / undersized tubers) can be separated from the crop stream at an early stage of picking by use of pre-cleaning rollers.

- Chassis

- Offset trailed machine: Tractors with wide wheels ensure an increased traction

- 40 kmph for road travelling

- Perfectly comfortable

- Video system for improved monitoring of the main webs and separators, to enable an optimum machine operation

- Easy to pull intake

- Due to the maintenance-free drive for the second main web and the deviner web, wear is minimized.

- Hydraulically driven picking web is mounted in a nearly horizontal position for ergonomical picking

- The potatoes can be inspected from all sides with the aid of a potato turning device (two rollers in picking table)

- To improve comfort of the picking staff a canopy is available

- Versatility

- The machine can be equipped with a windrow intake, exchangeable with quick-change system, for the delayed, discontinuous ("two-phases") harvesting process.

- Depending on the cultivation method (rows, beds, flat beds etc.), a wide range of different vegetables can also be harvested besides potatoes.

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Drawbar eye under or above PTO shaft

- Hydraulic jack stand

- Hydraulic drawbar steering

- Hydraulic axle steering

- Hydraulic levelling

- Wheels 400/70-20

- Offset pulled intake section with pulled, spring loaded disc coulters, different intake widths of 580, 620 and 660 mm are available.

- 2- or 3-piece share blade

- 2 outer haulm feed in rollers DM 400 mm

- 1st main web 32, 35, 40, 45 or 50 mm pitch

- 2nd main web 28, 32, 35 or 40 mm pitch

- Driven rotary agitator in 1st main web

- Deviner web with 6 retainer combs

- Mechanical drive of 1st and 2nd separator

- Mechanical height adjustment for double extracting roller in the 1st separator via bowden cable

- Platforms at both sides of the picking web

- Easy pick chute r/h-side

- Automatic picking web switch-off

- Final conveyor can be lowered hydraulically

- Analog system to operate the machine

- Speed adjustment (Bowden cable) for picking table web and finger web at picking table

- Bunker unloading height 3850 mm

- Bunker capacity with filling optimization: approx. 4000 kg

- Warning system for tractor driver

- Pressure-free return valve required from tractor

- LS connection

- MOT certification (Germany), brakes and road lights

Technical data

SE 140

| Dimensions | |

|---|---|

| Length | 8300 mm |

| Width | 3000 mm |

| Height | 3160 mm |

| Weight | |

| Empty weight with basic configuration | 5000 kg |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Drawbar eye | x |

| Drive | |

| Input speed p.t.o.-shaft | 540 rpm |

| Main webs | |

| 1st main web width | 750 mm |

| 2nd main web width | 750 mm |

| 1st main web sieving area | 1,48 m² |

| 2nd main web sieving area | 1,71 m² |

| Separators | |

| Deviner web width | 850 mm |

| 1st separator width | 980 mm |

| 2nd separator width | 650 mm |

| Picking table | |

| Width | 684 mm |

| Trash web width | 360 mm |

| Picking personal | 4+2 |

| Bunker | |

| Capacity | 4000 kg |

| Unloading height | 3850 mm |

| Wheels | |

| Wheels | 400/70-20 |

| Chassis and engine | |

| Air brake | x |

| Hydraulic brake | x |

| Transport speed (option) | 20 / 30 / 40 km/h |

| Tractor requirements | |

| Engine power (min.) | 55 kW |

| Oil flow | 34 l/min |

| Required control valves (single acting) | 1 |

| Non-pressurized return flow | 1 |

| Required control valves (double acting) | 1 |

| Permitted bearing load drawbar | 1000 kg |