VARITRON 470

INCREASED COMFORT, MORE POWER

The four-row, self-propelled potato harvesters VARITRON 470 with wheel chassis and VARITRON 470 Platinum TERRA TRAC will be equipped with new innovations.

New cabin

For a quiet and comfortable workplace, a new premium comfort cabin with optimised noise insulation is now optionally available. An additional increase in comfort is achieved by the new premium driver's seat. The leather seat with extra high back, the active ventilation, seat heating and air suspension with adjustable shock absorption offer the driver a relaxed workplace. The leather seat cover allows to remove any dirt easily and quickly. Other features including a large cooling box and a radio with a hands-free kit are also part of the new cab's equipment. Windshield wipers and sun blinds on all windows ensure a pleasant view in rain and sunshine.

Fully automatic speed adjustments

Two assistance systems based on "GRIMME-Speedtronic" ensure that the harvester can always be driven in the optimum range between performance and crop protection. "Speedtronic-Web" increases throughput by an automatic adjustment of the main web speed in relation to working speed and thus improves crop protection. To avoid any blockages in the ring elevator, its conveying speed is temporarily increased by "Speedtronic-Elevator" in the case that the pressure of the hydraulic system exceeds a defined target value. The driver is relieved from manual monitoring and control jobs and can therefore fully concentrate on the entire harvesting process.

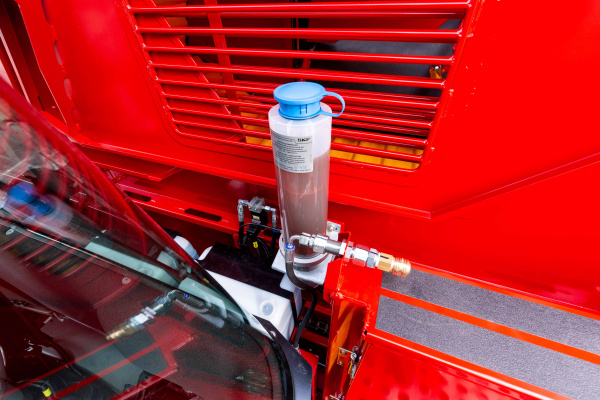

Automatic bunker chain lubrication

A bunker chain greasing system is standard from 2020 on. The greasing system ensures a longer durability of the bunker chain and increases the comfort for the user as manual greasing becomes void.

More power

Both versions of the VARITRON 470 are equipped with a modern, strong 6-cylinder diesel engine of Mercedes-Benz with 10.7 litre cubic capacity and 460 hp / 340 kW instead of 435 hp / 320 kW, including exhaust emission stage V.

Connection to myGRIMME

As standard, all GRIMME self-propelled harvesters are equipped with a telemetry unit that enables a connection to the customer portal myGRIMME. In combination with the software-module "myJobs", the system is able to differentiate automatically between road- and field-mode and thus can independently generate tasks. Manually inputting data is no longer necessary. This saves valuable working time and minimizes potential errors. After completing a job the user receives a detailed overview including all important process parameters, such as fuel consumption, time per working state and weather conditions for example. Additionally the lanes are marked in colours according to the work status. The data generated in this way provides the farmer an optimum basis for billing jobs and for possible optimization of work steps.

If the user uses a certified agricultural software, farm management information system (FMIS), it is possible to connect this software via the data exchange platform agrirouter with myGRIMME. On request, you can than send machine and GPS data from the machine to the FMIS.

For all self-propelled GRIMME harvesters, there are individual agreed service packages available which include the full service inclusive of wearing parts in the highest stage PROTECT.

The VARITRON series has been made in our purpose built factory in the "Niedersachsenpark" (Rieste/Germany) since 2011, with the most modern, advanced equipment and is one of the best selling self-propelled harvesters in the world.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates