scroll and find out more...

Self-propelled harvester - 2-row | VARITRON 220 Platinum TERRA TRAC

2-row, 2 t unloading bunker, high separation with rubber tracks, 354 HP

Self-propelled harvesters convince with a perfectly matched combination of performance, driving comfort and manoeuvrability. The resulting harvest reliability, even under the most difficult conditions, plays a decisive role in many cases. With its VARITRON 220 Platinum TERRA TRAC, GRIMME offers a powerful 2-row self-propelled harvester with rubber track, which can be equipped with a wide range of different separators. The intermediate bunker, with a capacity of 2.0 t, and the cart elevator are particularly suitable for direct loading into boxes or onto trailers during the continuous harvesting process. The telescopic rear axle allows the right rear wheel to be extended by impressive 550 mm. In combination with the rubber track, driving stability and safety reach their absolute maximum.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

With two separators as standard

It is possible to choose between a combination of roller separator (RS) and MultiSep as well as a double MultiSep.

Nonstop digging

The 2 t buffer bunker enables real non-stop harvesting. The productivity of the harvester can thus be increased.

Convenient and crop protective box filling

The box filling chute on the elevator makes it easier to fill boxes, especially when emptying the bunker during harvesting. The box filling chute additionally reduces the drop step and thus increases crop protection

Comfort Cab with premium comfort seat

The new low-noise ErgoDrive cab with the air-suspended comfort seat including active ventilation and seat heating ensures a comfortable working day.

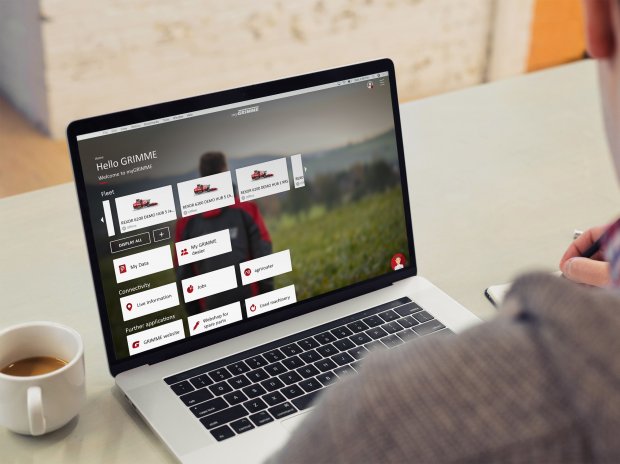

myGRIMME - Your digital gateway to GRIMME

With the virtual machine file, you have all your machines, services and documents available - anytime at a glance. The smart documentation records and analyses all machine jobs quickly and without manual data entry. Order the perfect spare parts for your machines easily and intuitively in the myGRIMME Shop.

Discover now!

Benefits

- Digging unit

- TerraControl digging depth adjustment, which ensures also in changing conditions an optimum sieving output and high gentle crop handling at the same time.

- High acreage performance and separating effect.

- With the reverse system, the intake web as well as the first and the second main web are independently reversible to minimize the risk of blockages.

- With the patented Vario-RS, the infinitely roller distance adjustment, it is possible to react to different crop sizes and harvesting conditions at any time (without roller change).

- The MultiSep performs also on cloddy, sticky soils and soils containing small stones a low-loss and effective trash separation.

- 2 t buffer bunker with 1200 mm wide cart elevator rear of the cab for direct loading into boxes on the trailer.

- Picking platform with enough space for up to 4 persons

- Chassis

- In combination with the telescoping rear axle for the first time a machine width under 3.5 m is realizable in conjunction with narrow wheels (option) and row width 75 cm.

- For digging it is possible to extend the right rear wheel by impressive 550 mm which ensures highest driving stability.

- The ground protective rubber tracks allow good harvesting also in wet fields.

- Perfectly comfortable

- Speedtronic-Web: Completely automatic speed control of the main webs depending on the driving speed.

- ErgoDrive operating concept with multi-functional lever (= individual programming of all main functions to the first operator level for direct access), keypad integrated into an ergonomic armrest, one touch-screen terminal CCI 100 and one touch-screen terminal CCI 50. As an option two touch-screen terminals CCI 100 can be configured.

- Visual Protect automatically switches to that camera, where a new adjustment was carried out or a critical situation has been noticed (risk of a separator blockage e.g.), so the driver can react and prevent further blockages.

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Pulled intake section with 4 pulled, spring loaded disc coulter, intake width of 580 or 620 mm

- TerraControl

- Row width 75 cm

- 2-piece share or 3-piece share

- 2 diablo roller Ø 390 mm with flat shoulder

- 2 outer haulm feed in rollers and centre retaining rubber

- Intake web pitch: 35, 40, 45 or 50 mm pitch

- Pitch dependent PU drive of the intake web

- 1st main web pitch: 28, 32, 35, 40, 45 or 50 mm pitch

- Pitch independent friction drive of the 1nd main web

- Hydraulically driven and speed adjustable rocker agitator in 1st main web

- hydraulically driven and reversible extracting unit following the 1st main web

- 2nd main web pitch: 28, 32 35, 40 or 45 mm pitch

- Pitch independent friction drive of the 2nd main web

- 1nd separator: Roller separator or MultiSep

- Levelling device for MultiSep or roller separator

- Hydraulic drive, including an automatic to reverse the second haulm extracting unit

- 2nd separator: MultiSep following Roller Separator or 1st MultiSep unit

- Hydraulically driven, 1800 mm wide C-elevator with PVC-canvas

- 1630 mm wide picking table. It offers enough place for up to 4 persons.

- 2 t buffer bunker with 1200 mm wide cart elevator rear of the cab

- Mercedes-Benz (MTU) engine OM 936 LA: 260 kW / 354 HP stage V, using SCR exhaust technology (AdBlue)

- Speed 20 kmph or 25 kmph

- 2 steerable front wheels with hydraulic side travel +/- 150 mm

- 300/95 R42 front wheels

- Wheels rear, r/h-side 800/65 R32

- Extendable right rear wheel for maximum driving stability

- Rubber track rear l/h-side 800 mm wide

- Hydrostatic single wheel drive with on - demand traction control (ASR)

- LED-working lights

- Compressor

- Driver cab with 6 LED-working lights, heated and electrical adjustable mirrors and windshield wipers on all windows.

- ErgoDrive operating concept with multi-functional lever (= individual configuration of all main functions to the first operator level for direct access), keypad integrated into an ergonomic armrest, one touch-screen terminal type CCI 100 and an additional touch-screen terminal type CCI 50.

- Clean Control: Central setting for all separators

- 1 colour monitor incl. rear camera and light

- Visual Protect: CAN-Bus controlled monitoring system

- Telemetric-unit called "GRIMME SmartConnect", as standard, with free connectivity to myGRIMME

- Version RS:

- Extracting roller against 2nd main web

- 1st separator: Roller Separator, consisting of 9 axial arranged roller pairs: hydraulically driven including reverse-automatic

- 2nd separator: MultiSep, consisting of 4 hydraulically driven roller pairs incl. reverse-automatic electronic and drive direction change of the plain rollers, separate hydraulic height and distance adjustment of the plain rollers, one transfer web into the up and over elevator

- Version MS:

- 2nd extracting unit against 2nd main web

- 1st separator: MultiSep, consisting of 4 hydraulically driven roller pairs incl. reverse-automatic electronic and drive direction change of the plain rollers, separate hydraulic height and distance adjustment of the plain rollers

- 2nd separator: MultiSep, consisting of 4 hydraulically driven roller pairs incl. reverse-automatic electronic and drive direction change of the plain rollers, separate hydraulic height and distance adjustment of the plain rollers, one transfer web into the up and over elevator

Technical data

VARITRON 220 Platinum TERRA TRAC

| Dimensions | |

|---|---|

| Length | 11700 - 13395 mm |

| Width | 3300 - 4023 mm |

| Height | 3880 mm |

| Working width | |

| Row width | 75 - 90 cm |

| Intake width | 540 / 580 / 620 mm |

| Main webs | |

| Intake web width | 1500 mm |

| 1st main web width | 1700 mm |

| 2nd main web width | 1700 mm |

| Sieving area intake web | 2,9 m² |

| 1st main web sieving area | 3,4 m² |

| 2nd main web sieving area | 4,9 m² |

| Intake web pitch (choice of) | 35 / 40 / 45 / 50 mm |

| 1st main web pitch (choice) | 28 / 32 / 35 / 40 / 45 / 50 mm |

| 2nd main web pitch (choice) | 28 / 32 / 35 / 40 / 45 mm |

| Elevator | |

| Up and over elevator transport width | 1800 mm |

| Picking table | |

| Width | 1630 mm |

| Bunker | |

| Capacity | 2000 kg |

| Unloading elevator | |

| Width of overloading elevator | 1200 mm |

| Transfer height | 4200 mm |

| Wheels | |

| Front | 2x 300/95 R42 |

| Rear right | 800/65 R32 |

| Number of rubber tracks | 1 |

| Rubber track rear (B x L) | 800 x 2960 mm x mm |

| Contact length | 2000 mm |

| Steering angle | |

| Front | 60 ° |

| Rear | 7 ° |

| Chassis and engine | |

| Transport speed | 20 / 25 km/h |

| Motor power | 260 / 354 kW/HP |

| Fuel tank capacity | 600 l |

| AdBlue tank capacity | 40 l |